In a competitive market, businesses aim for both swift service and accurate results in tasks like coatings application and window tinting. To achieve this, they optimize processes with efficient workflows, leverage technology for automation (e.g., digital design platforms, advanced printing presses), and use suitable protective coatings or wraps. Key tools ensuring speed and precision include laser cutting machines, ceramic window tint films, and automated tinting machines, backed by digital design software. These modern solutions cater to customers' demands for quick turnaround times without compromising quality.

In today’s fast-paced business environment, achieving a quick turnaround time while maintaining accuracy is crucial for success. This article delves into the intricate balance between speed and precision, exploring strategies and tools that can optimize your operations. We’ll examine how understanding the impact of these factors enables businesses to enhance efficiency without compromising quality. Discover practical techniques to manage expectations, streamline processes, and ensure consistent, quick turnaround times.

- Understanding the Impact of Speed and Accuracy

- Strategies to Optimize Turnaround Time

- Tools and Techniques for Precision in Quick Turnarounds

Understanding the Impact of Speed and Accuracy

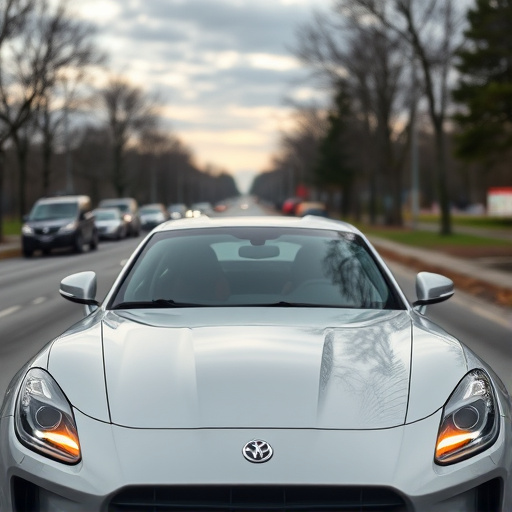

In today’s fast-paced world, a quick turnaround time is often seen as a competitive advantage for many businesses. However, balancing speed and accuracy is an art that requires careful consideration. Achieving a swift processing time while maintaining meticulous attention to detail can be challenging, especially in industries where precision matters most. Take, for instance, the automotive sector, where ceramic coatings or protective coatings application demands both expertise and efficiency to ensure optimal performance and aesthetics. Similarly, window tinting services need to strike a balance between rapid installation and precise cutting to meet client expectations.

Understanding the intricate relationship between speed and accuracy is pivotal. On one hand, prioritizing speed can lead to rushed work, potentially compromising quality. On the other hand, focusing solely on accuracy might extend turnaround times significantly. The key lies in optimizing processes, employing skilled professionals, and utilizing tools designed for efficiency without sacrificing precision. This delicate equilibrium ensures that businesses can deliver a high-quality product or service within an acceptable timeframe, thus fostering customer satisfaction and loyalty.

Strategies to Optimize Turnaround Time

To achieve a quick turnaround time while maintaining accuracy is a delicate balance that many businesses strive for. One effective strategy to optimize this process is by implementing efficient workflows and streamlining operations. This involves organizing tasks in a logical sequence, assigning priorities, and utilizing technology to automate repetitive functions. For instance, digital design platforms with cloud integration can enable remote collaboration and access to project files, reducing delays caused by file sharing.

Additionally, investing in the right tools and resources is vital. High-quality printing presses, advanced cutting machines, or specialized software for custom graphics can significantly speed up production without sacrificing accuracy. Ensuring vehicle protection through suitable coatings or wraps not only adds an extra layer of care but also contributes to faster preparation times between jobs.

Tools and Techniques for Precision in Quick Turnarounds

In the pursuit of swift turnarounds, precision becomes your secret weapon. The right tools and techniques can significantly enhance accuracy, ensuring that speed doesn’t come at the cost of quality. For instance, in car customization, advanced equipment like laser cutting machines can swiftly and precisely craft custom parts, revolutionizing the installation process. Similarly, for tasks involving heat rejection, such as window tinting, ceramic window tint films offer both speed and superior results. They install quickly and effectively manage heat transfer, a crucial aspect for any quick turnaround time service.

These modern solutions streamline workflows, minimizing errors and maximizing efficiency. For car customization projects, digital design software enables detailed planning, ensuring every cut and fit is precise. In the realm of window tinting, automated tint machines not only speed up application but also guarantee consistent results across multiple vehicles. By adopting these tools, businesses can achieve remarkable turnaround times while maintaining high standards of accuracy, catering to customers’ demands for both swift service and impeccable quality.

Balancing speed and accuracy is an art, especially when striving for optimal quick turnaround times. By understanding the intricate relationship between these two factors, businesses can implement effective strategies and utilize suitable tools. Through precise execution, teams can enhance productivity without compromising quality, ensuring a seamless and efficient process. Achieving this delicate balance is key to staying competitive in today’s fast-paced market.