In a competitive market, customers demand swift project completion, particularly for services like vehicle wraps and protective coatings. Businesses overcome this challenge by adopting digital printing technologies, establishing clear communication, efficient workflows, and meticulous craftsmanship to deliver high-quality results while meeting quick turnaround times, using tools like robotic applications and digital design software. Skilled technicians prioritize quality, following tailored standards and considering customer preferences, ensuring accurate and timely service that exceeds expectations.

In today’s fast-paced world, achieving a quick turnaround time without compromising quality is more crucial than ever. This article explores strategies and techniques that balance speed with excellence. We delve into efficient processes and meticulous attention to detail to ensure accuracy under tight deadlines. Discover how organizations are revolutionizing their approaches, optimizing workflows, and maintaining high standards in an increasingly demanding environment, all while delivering projects on time – the ultimate key to staying competitive.

- Balancing Speed and Quality: Strategies for Success

- Efficient Processes: Unlocking Quick Turnaround Times

- Ensuring Accuracy Amidst Time Constraints

Balancing Speed and Quality: Strategies for Success

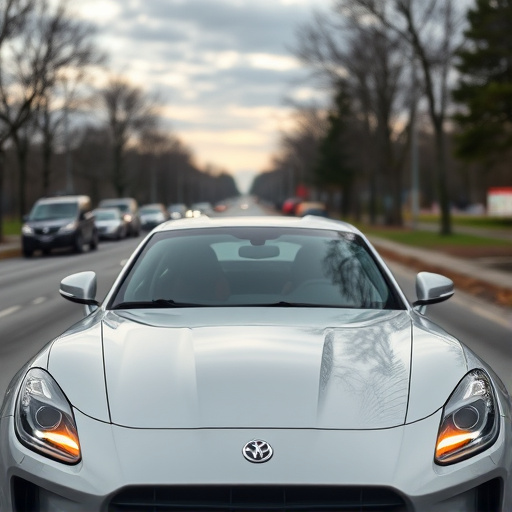

In today’s fast-paced world, customers expect quick turnaround times for their projects, especially when it comes to services like vehicle wraps and protective coatings. However, achieving rapid production without compromising quality can be a delicate balance. The key lies in implementing strategic approaches that streamline processes without sacrificing attention to detail. One effective method is adopting technology that automates certain tasks while still allowing for manual oversight to ensure accuracy. For instance, digital printing technologies can significantly reduce the time required for vehicle wrap design and installation.

Additionally, establishing clear communication channels between teams involved in the project lifecycle is vital. Effective collaboration ensures that everyone works towards a shared timeline without compromising quality standards. This might involve regular progress meetings, clear task delegation, and accessible project management tools. Custom vehicle wraps, for example, require not just speed but also precision to align graphics perfectly on a moving vehicle. By combining efficient workflows with meticulous craftsmanship, businesses can deliver high-quality results while meeting the demand for quick turnaround times.

Efficient Processes: Unlocking Quick Turnaround Times

Efficient processes are the cornerstone of achieving quick turnaround times without compromising quality, especially in demanding industries like automotive customization. Companies specializing in ceramic window tinting, vehicle enhancement, or vinyl wraps have found innovative ways to streamline their operations. By implementing cutting-edge technology and well-defined workflows, they can significantly reduce processing time while maintaining high standards.

For instance, automation plays a pivotal role in expediting these processes. Robotic applications, for ceramic coating and window tinting, ensure consistent precision and speed, minimizing human error. Additionally, digital design tools enable faster creation and customization of vinyl wraps, allowing for more complex and intricate patterns without prolonging production times. These streamlined methods not only fulfill customer demands for quick services but also enhance overall productivity and satisfaction.

Ensuring Accuracy Amidst Time Constraints

In the pursuit of achieving quick turnaround times, maintaining accuracy becomes a delicate balance. Time constraints often lead to high-pressure environments where precision can slip through the cracks. However, this doesn’t have to be the case, especially in industries like car customization and window tinting, where meticulous attention to detail is paramount. Skilled technicians understand that sacrificing quality for speed is counterproductive. They employ strategic planning and specialized tools to ensure every step of the process is executed with precision, even under tight deadlines. This involves meticulously following standards and procedures tailored to each unique project, ensuring not just timely delivery but also superior results.

For example, in car customization and heat rejection window tinting, accurate measurement and installation are crucial. Technicians must consider various factors like vehicle models, specific preferences of the customer, and environmental conditions to deliver a perfect fit and function. By adhering to strict quality control measures and utilizing advanced technologies, they can meet tight deadlines without compromising on accuracy. This ensures that clients receive high-quality services that not only meet but exceed their expectations, even when quick turnaround times are the priority.

In conclusion, achieving a quick turnaround time without compromising quality is no longer a distant dream. By implementing efficient processes and balancing speed with accuracy, businesses can excel in meeting tight deadlines while maintaining high standards. Embracing strategic approaches, as discussed in this article, allows for streamlined workflows, ensuring that both timeliness and excellence go hand in hand. The key lies in optimizing every step, from streamlining operations to empowering teams, ultimately resulting in a competitive edge driven by swift yet superior output—a true testament to modern productivity.